How to Customized your own puzzle

2023-07-14

Identify Requirements: First, clarify your needs and expectations for the customized puzzle. Consider aspects such as the material, shape, size, design, and quantity of the puzzle.

Contact Suppliers: Get in touch with puzzle manufacturers or suppliers and communicate your custom requirements to them. Inquire about their customization services, available material options, and pricing information.

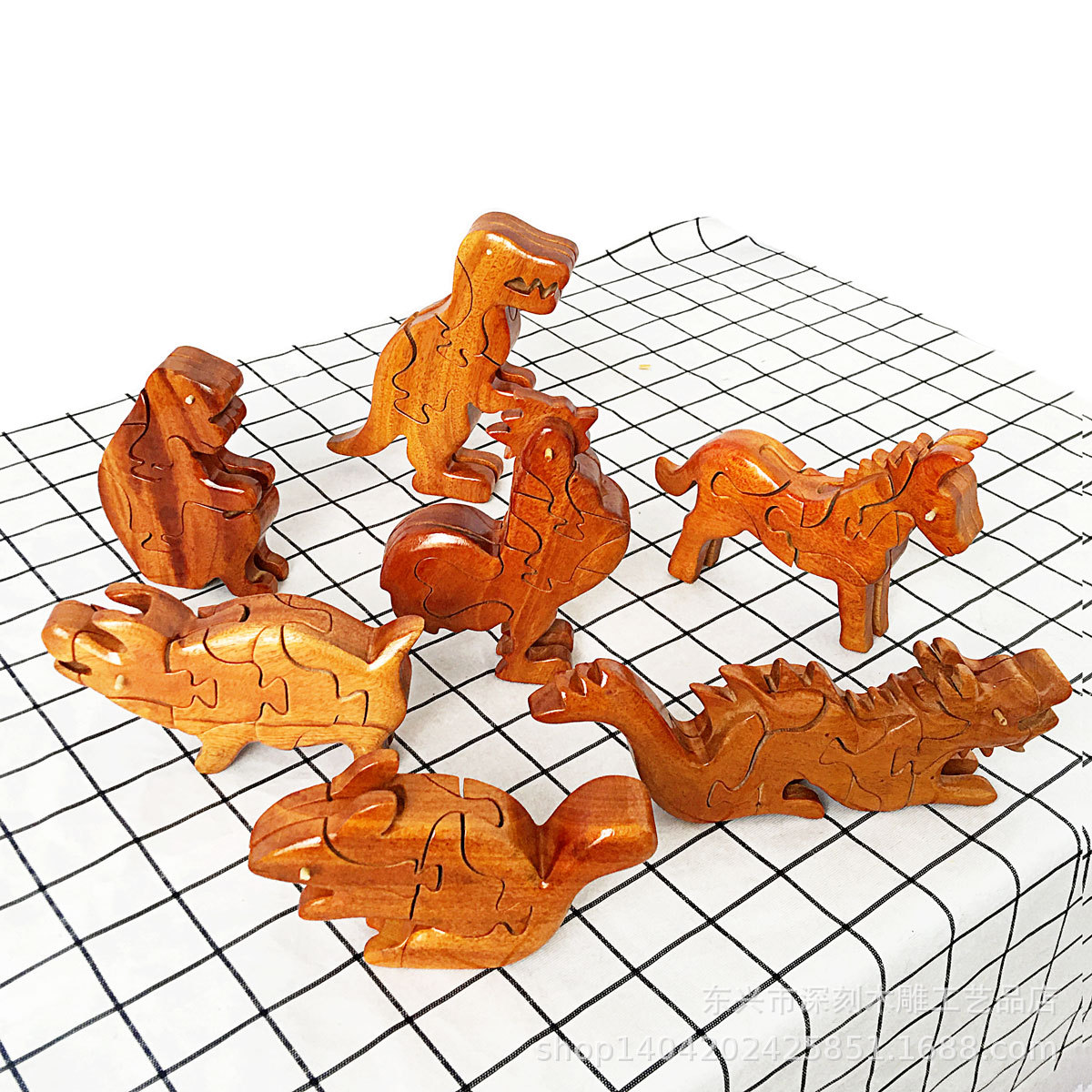

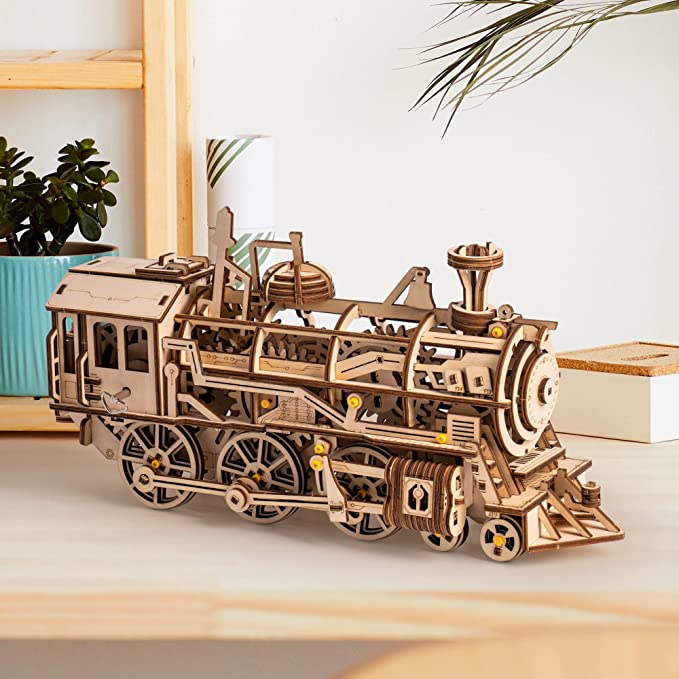

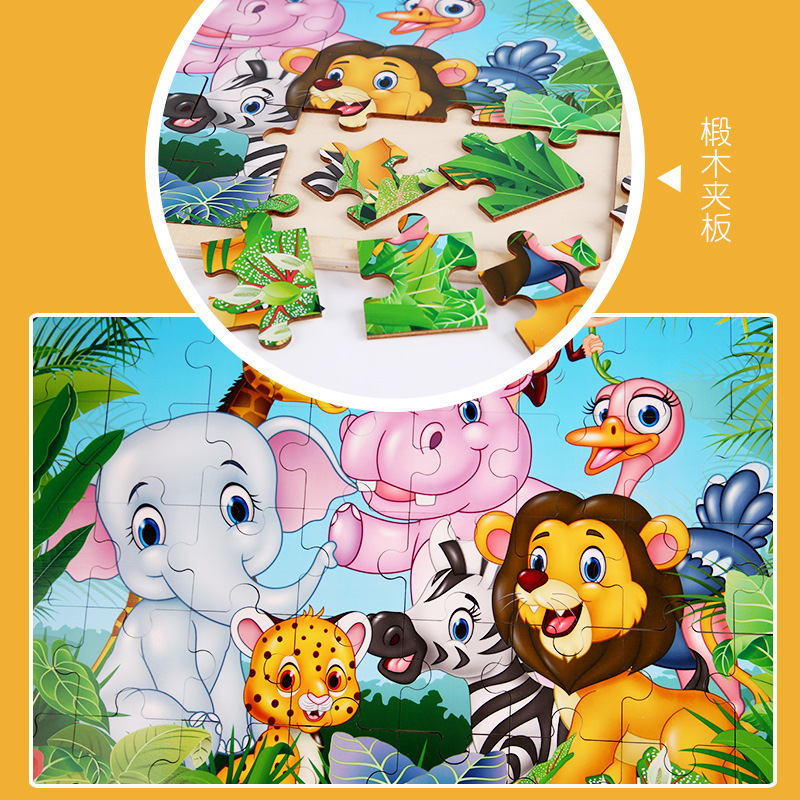

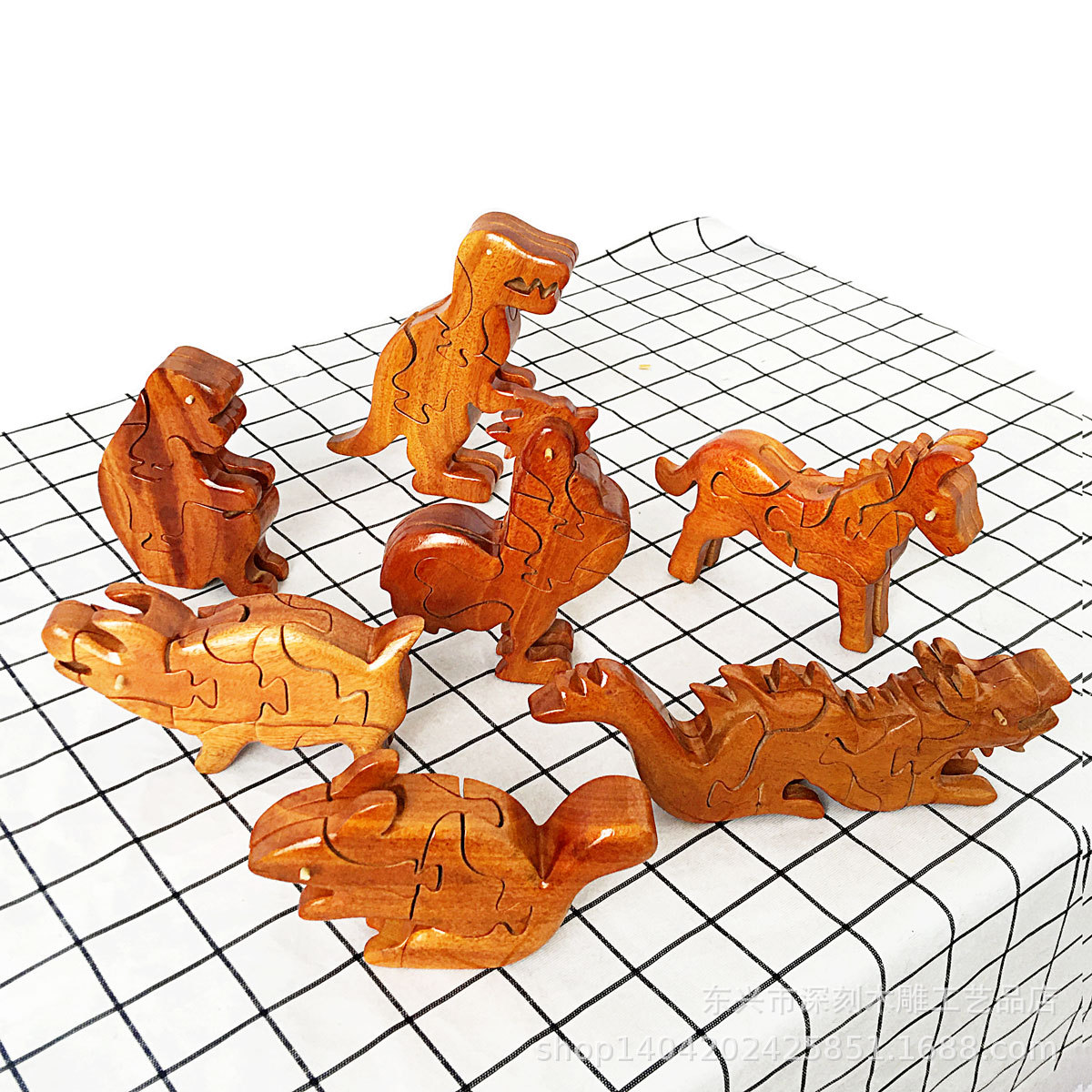

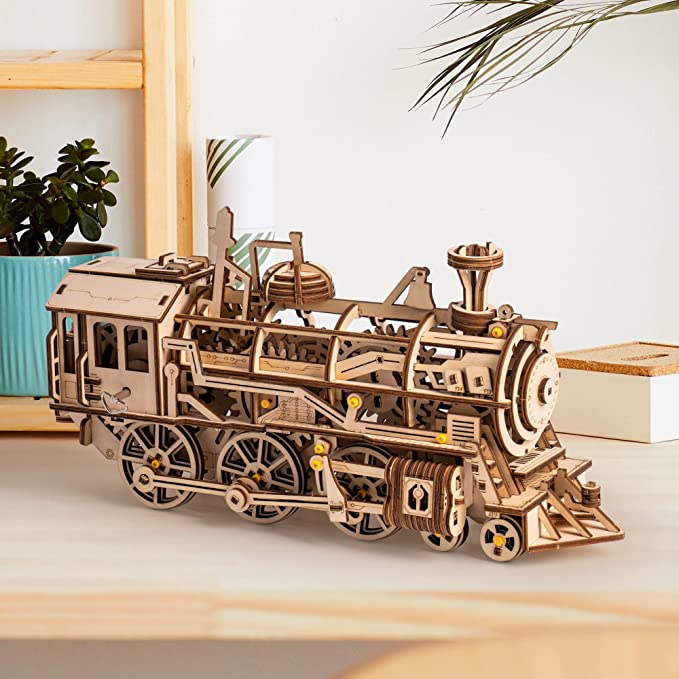

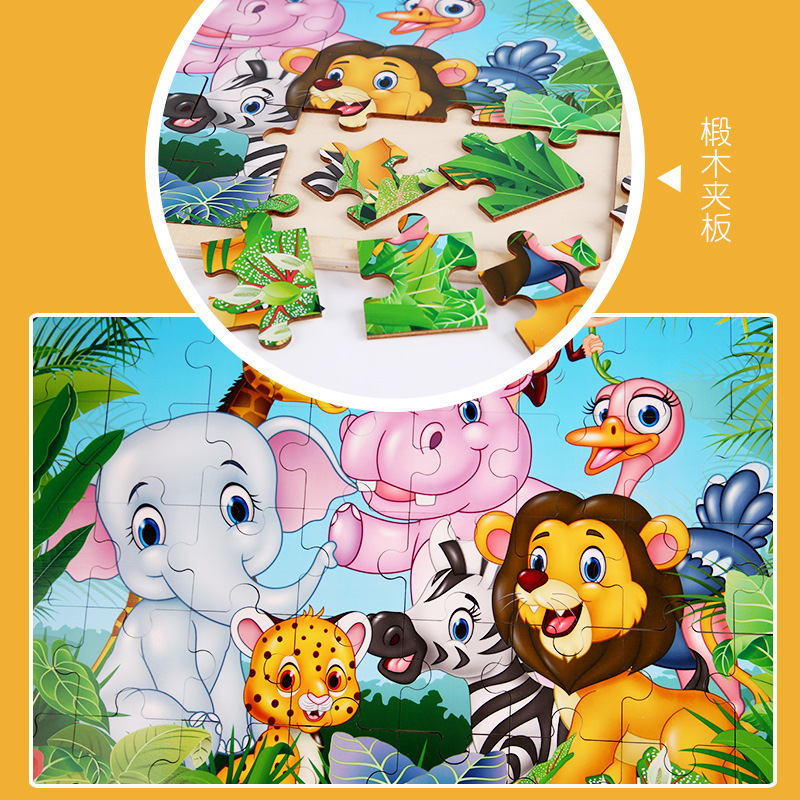

Select Materials and Sizes: Based on your preferences and budget, choose suitable puzzle materials like wood, paper, plastic, etc., and determine the desired puzzle sizes.

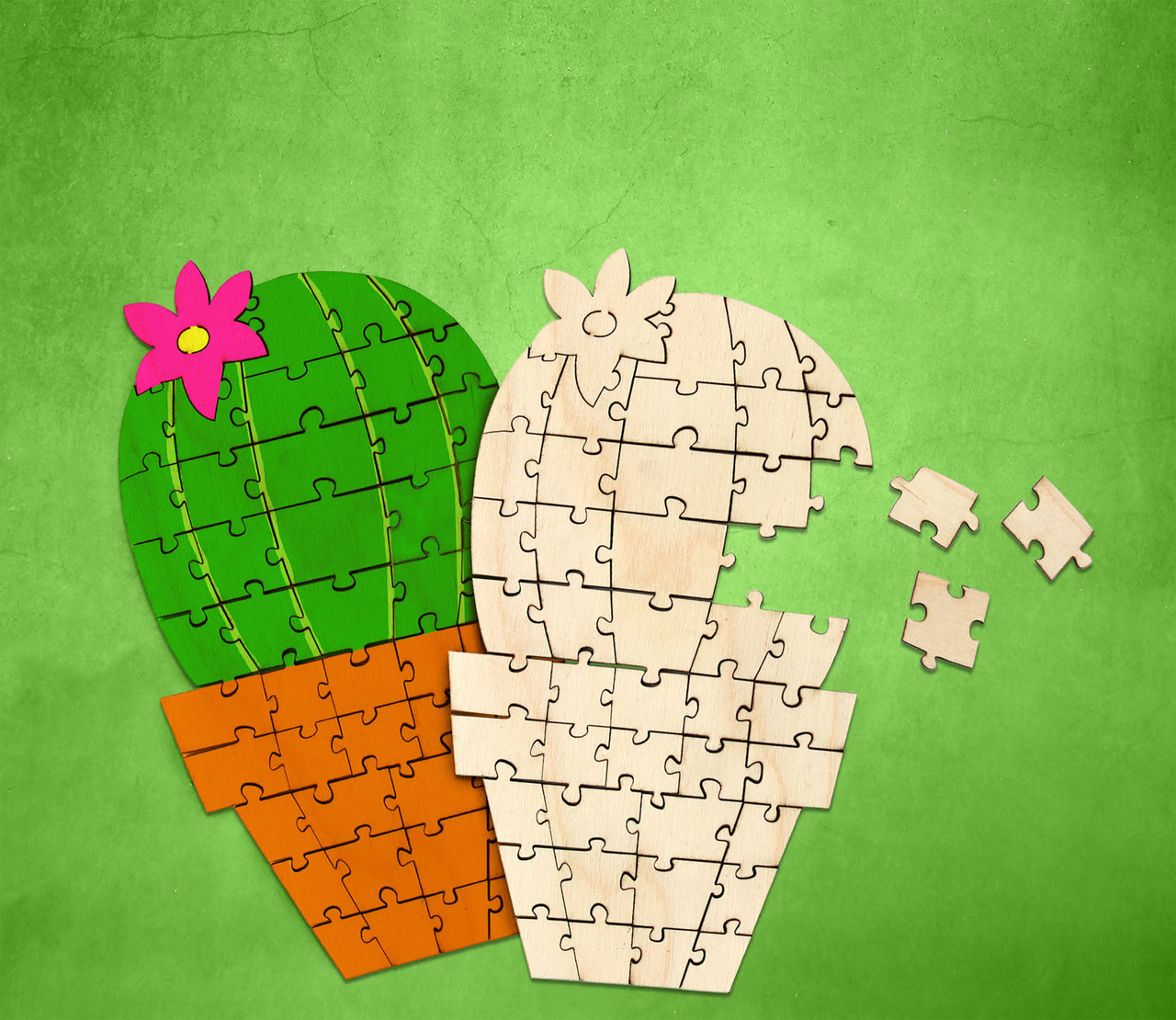

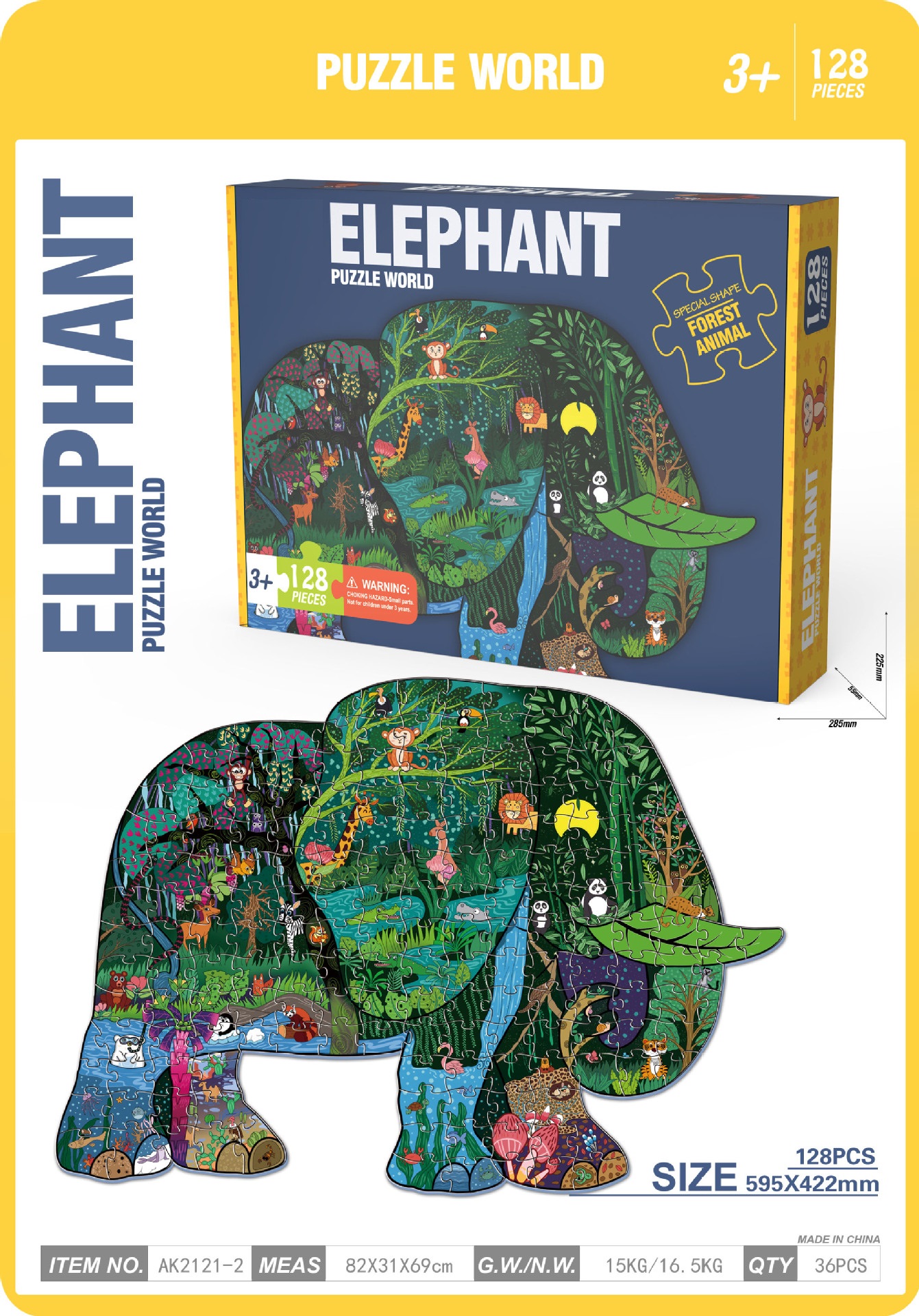

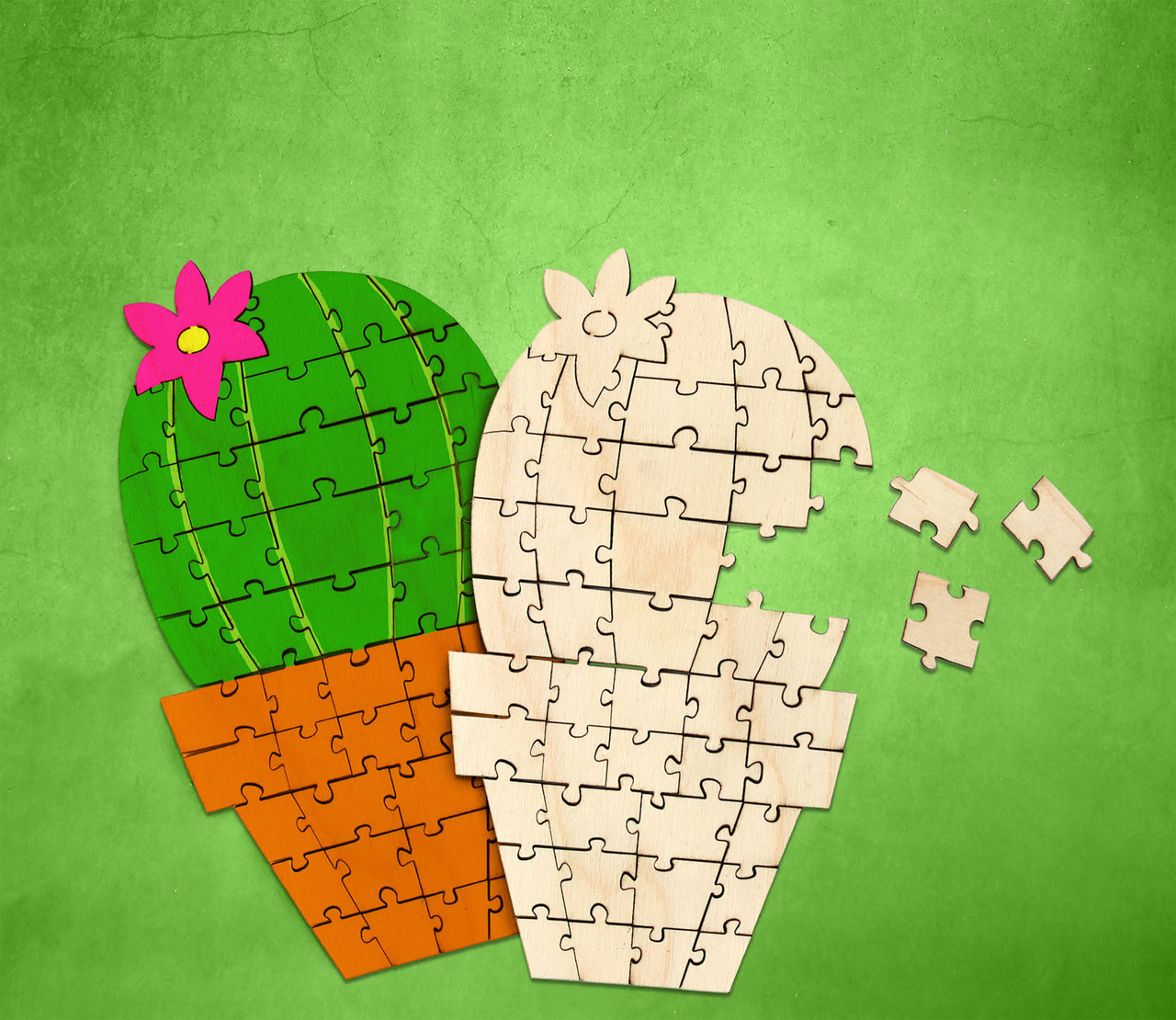

Design and Patterns: If you have specific patterns, images, or designs in mind, provide them to the supplier for customization. If you need help with the design, consult with the supplier's design team and provide relevant reference materials. Sample Confirmation: Before commencing full-scale production, request samples or design drafts from the manufacturer for review. Check if the samples align with your expectations and suggest any necessary modifications.

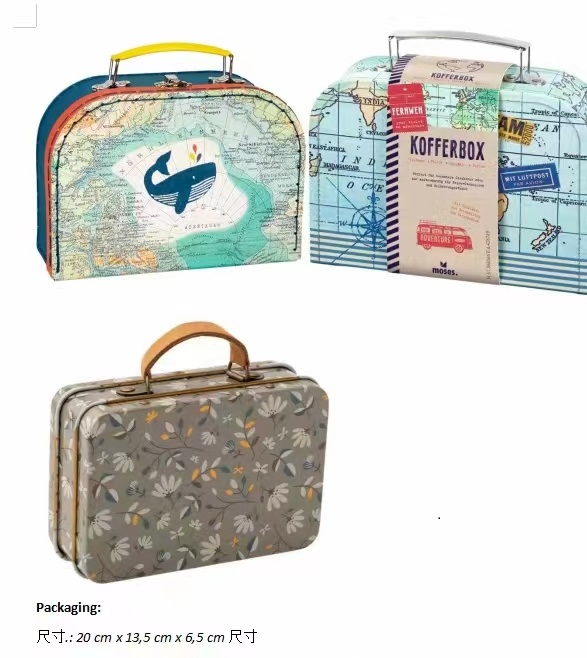

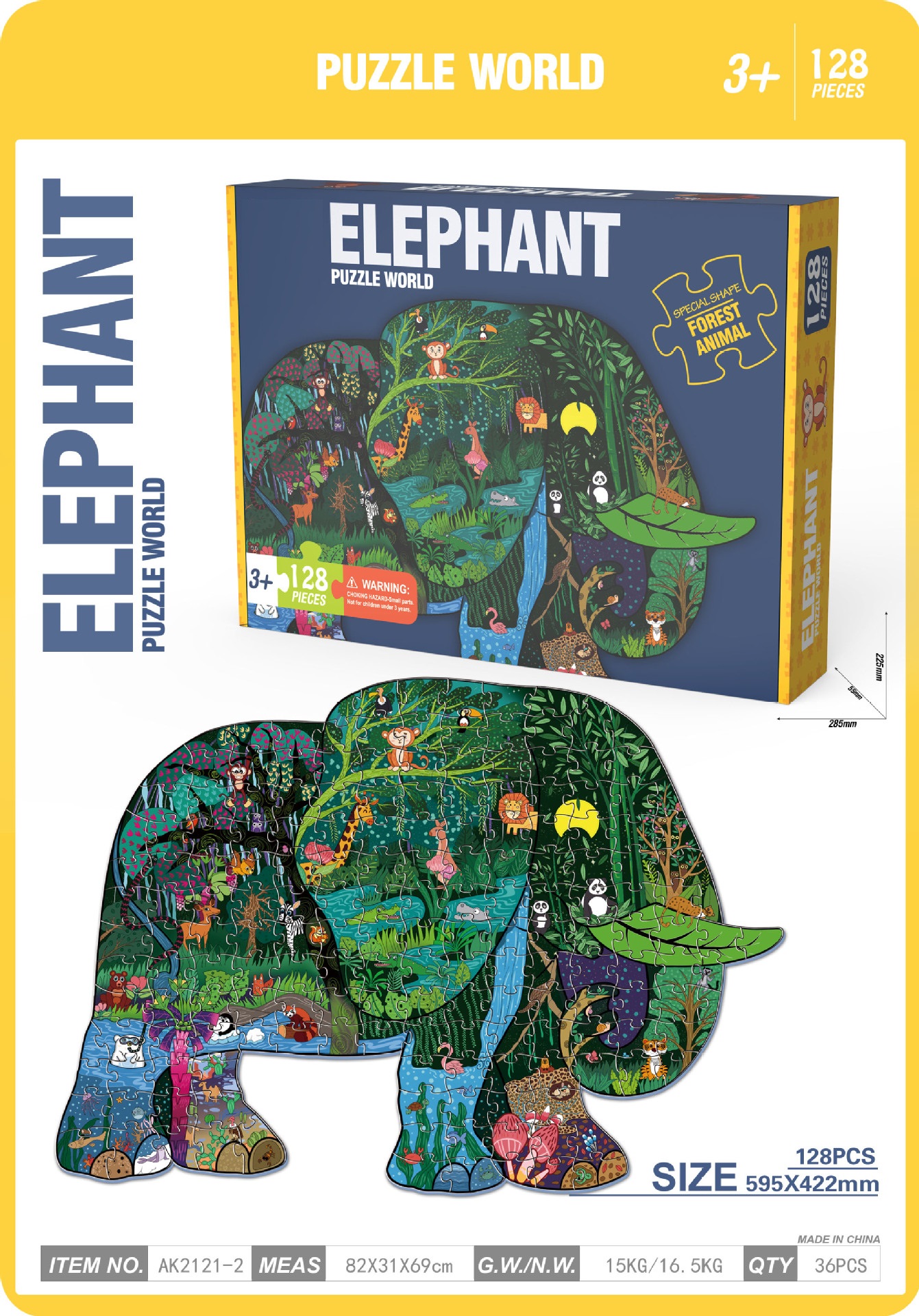

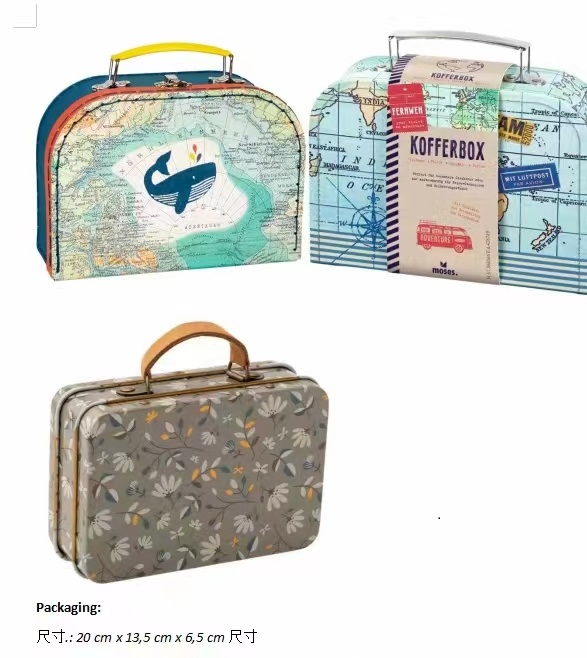

Packing:Please don’t forget the packing, like color box, tube, bag, box etc.

Production and Quality Control: Once the samples are approved, the manufacturer will initiate the production of the custom puzzle. Throughout the production process, rigorous quality control measures are implemented to ensure the puzzle's quality and accuracy.

Delivery and After-Sales Service: Upon completion of the custom puzzle production, the manufacturer will arrange for delivery. Discuss and confirm the delivery method and timeline with the supplier. Additionally, inquire about any after-sales services or support provided by the supplier.

Please note that the exact steps and details of the custom puzzle process may vary among manufacturers. It is important to communicate extensively with the supplier and ensure clarity regarding all requirements and specifications, thus ensuring that the final custom puzzle meets your expectation.

Contact Suppliers: Get in touch with puzzle manufacturers or suppliers and communicate your custom requirements to them. Inquire about their customization services, available material options, and pricing information.

Select Materials and Sizes: Based on your preferences and budget, choose suitable puzzle materials like wood, paper, plastic, etc., and determine the desired puzzle sizes.

Design and Patterns: If you have specific patterns, images, or designs in mind, provide them to the supplier for customization. If you need help with the design, consult with the supplier's design team and provide relevant reference materials. Sample Confirmation: Before commencing full-scale production, request samples or design drafts from the manufacturer for review. Check if the samples align with your expectations and suggest any necessary modifications.

Packing:Please don’t forget the packing, like color box, tube, bag, box etc.

Production and Quality Control: Once the samples are approved, the manufacturer will initiate the production of the custom puzzle. Throughout the production process, rigorous quality control measures are implemented to ensure the puzzle's quality and accuracy.

Delivery and After-Sales Service: Upon completion of the custom puzzle production, the manufacturer will arrange for delivery. Discuss and confirm the delivery method and timeline with the supplier. Additionally, inquire about any after-sales services or support provided by the supplier.

Please note that the exact steps and details of the custom puzzle process may vary among manufacturers. It is important to communicate extensively with the supplier and ensure clarity regarding all requirements and specifications, thus ensuring that the final custom puzzle meets your expectation.